Several studies show that around 70% of the energy consumed in manufacturing companies corresponds to electric motors. This use includes water pumping, air compression and other indirect applications of electric motorization.

The motors represent a minimum saving potential of 10% when changing from inefficient IE1 motors to efficient IE3 motors (ZVEI, electric drives division -2008)

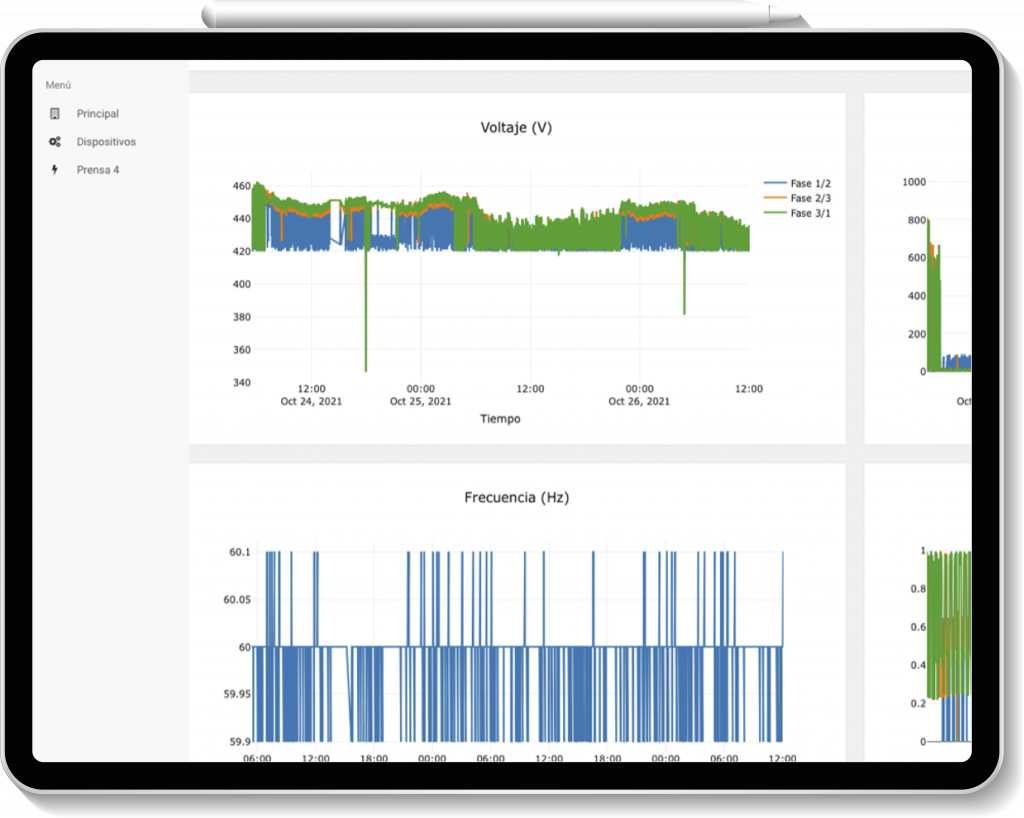

The efficiency monitoring service in electric motors consists of measuring variables such as kilowatts lost due to unbalances, kilowatts lost due to harmonics, neutral current, power factor and other variables related to efficiency such as changes in technology, the use of variable speed drives or maintenance.

Main features

Easy-to-install sensors

Custom dashboard configuration

prediction of energy saving potential